.0125 in Inches Fraction, Millimeters, Meter, Foot, Cm & MM

If you’ve ever come across the number 0.0125 in inches, you might have wondered just how small it really is. If you’re in machining, engineering, or just trying to make sense of a measurement you saw online, you are at right place because understanding this tiny fraction of an inch can be surprisingly useful.

In this guide, I’ll break it down into simple terms and show you conversions. I will also compare it to everyday objects and explain where it’s commonly used.

How Big Is 0.0125 in Inches?

Check also: 0.094 As a Fraction or What is 0.11811 Inches to Fraction.

0.0125 inches is incredibly small about ¹⁄₈₀ of an inch.

To put that into perspective:

- It’s thinner than a sheet of standard printer paper.

- It’s roughly the thickness of three human hairs stacked together.

- It’s smaller than the gap between two stacked coins.

If you don’t work with precision measurements every day, it can be hard to visualize. That’s why I recommend thinking of it as “about one-eightieth of an inch” that is a tiny sliver in the world of measurements.

0.0125 in Inches in Different Units

A lot of people search for “0.0125 inches to mm” or “0.0125 inches to cm” because metric measurements are often easier to picture. Here’s the conversion:

- Millimeters (mm): 0.0125 × 25.4 = 0.3175 mm

- Centimeters (cm): 0.03175 cm

- Microns (µm): 317.5 µm

This size is so small that most rulers won’t help. You’d need a micrometer or digital caliper to measure it accurately.

You can also check K5 Learning Worksheets or Cursive Alphabet Worksheets.

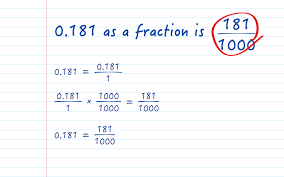

0.0125 Inches as a Fraction

In fractions of an inch, 0.0125 inches = 1/80 inch. This is a neat conversion because 80ths of an inch are common in fine machining and custom engineering.

Where You Might See 0.0125 Inches in Real Life?

This isn’t a random number, you’ll often find 0.0125 inches in technical and manufacturing contexts:

- Machining tolerances: When parts must fit together perfectly, machinists work within tolerances as small as ±0.0125 inches.

- Sheet metal thickness: Specialty metals for electronics or aerospace can be made this thin.

- Paper and plastic film: Certain premium papers or thin films for packaging can be in this range.

- Electronics components: Circuit boards, connector pins, and shims sometimes use measurements close to 0.0125 inches.

How to Measure 0.0125 Inches like a pro?

Because it’s such a small size, your options for measuring are limited. Here’s how professionals do it:

- Micrometer: Accurate down to 0.0001 inches.

- Digital Calipers: Good for a quick reading but less precise than micrometers.

- Thickness Gauges: Often used for metal sheets or films.

Why This Size Matters?

You might be thinking that “Why would anyone care about something so small?”

In precision engineering, a difference of 0.0125 in inches can be the line between a perfect fit and a failed part. In industries like aerospace or electronics, every thousandth of an inch counts.

FAQ’s Section

Conclusion

If you deal with manufacturing, machining or any field where accuracy matters, keep this number in mind. It’s a reminder that sometimes, the smallest details have the biggest impact. Hope you like this information.